Summary of Services

A road surface inspection system that utilizes smartphones

The "DRIMS" offers an efficient road management and reduces burden on personnel.

Many local governments cite the maintenance of road pavements as an issue. Measures to prevent deterioration of road pavements are an urgent priority, in part because they became subject to inspection under the national pavement inspection guidelines in the fall of 2016.

Conducting full-scale inspections (MCI) using specialized vehicles is too costly, which only leaves the option of conducting visual inspections, which in turn increases the burden on road managers. This is the reason behind the development of the road monitoring system "DRIMS".

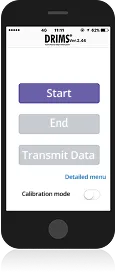

Highly precise road surface inspections (estimating IRI) are made possible by combining sensors built in smartphones (acceleration, angular velocity and GPS) with our proprietary technology. Anomalies on the road surface can be detected automatically, by mounting a smartphone on a vehicle owned by the local government. This facilitates implementation of planned preventive measures and establishment of an organization that is capable of providing rapid responses to reports and inquiries from residents, which in turn makes it possible to conduct efficient road management without burdening personnel.

* IRI (International Roughness Index)

Proposed by the World Bank in 1986. A scale for an objective evaluation of the ride comfort on road pavement is considered

to have a particularly high correlation with the bodily sensation of ride comfort.

Video available on YouTube.

The "DRIMS" solves various issues of road management.

01The inspection range is so broad that visual inspection can only provide a limited capability

The "DRIMS" makes it possible to inspect road surfaces automatically by mounting the vehicle mounted device (smartphone) on the commercial vehicle used for daily work.

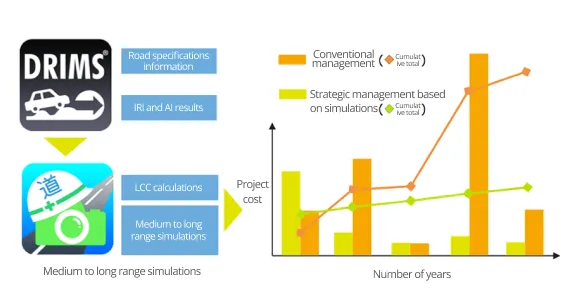

02Obtaining a budget for road repair work is difficult

Planned preventive maintenance measures can be implemented and evidence that back budget requests can be collected and facilitate maintenance cost reductions in the future, simply by linking the data of the "DRIMS" with the "Michinosuke" (road asset management system)

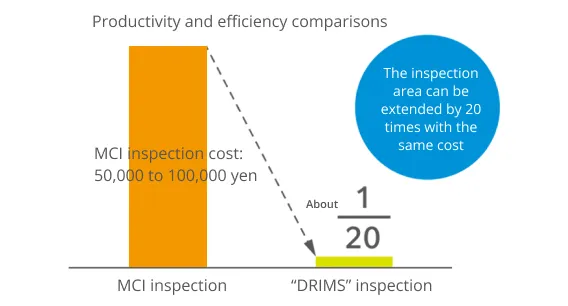

03Inspections that use special vehicles are extremely expensive

The cost of inspections using the "DRIMS" is about one-twentieth of the cost of inspections conducted by special vehicles. This means that about 20 times as many inspections can be performed at the same cost.

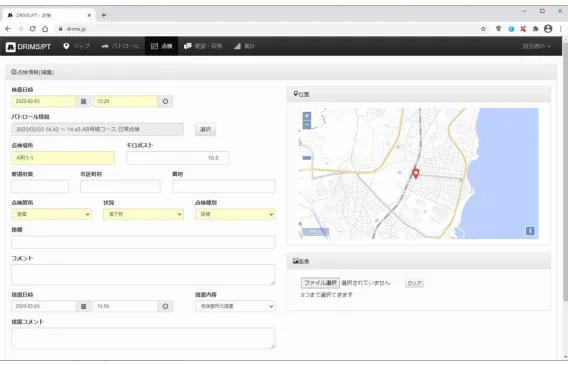

04Unable to respond rapidly to reports from residents

Information on day-to-day requests and complaints can also be registered and displayed on a list or on a map. Status management is also available, making smooth responses possible.

05Precision is uncertain with inspections conducted with a smartphone

The "Technology for Simplified Survey of Road Surface Conditions" issued by the Ministry of Land, Infrastructure, Transport and Tourism (published on December 28, 2018) ranks IRI highest out of 14 companies. This is a technology that utilizes a smartphone, yet it is capable of recording detection and hit rates that are equivalent to those acquired by special vehicles.

Combining our proprietary technology with the smartphone facilitates high-precision inspections.

01 Characteristics of the vehicle used for taking measurement are identified during initial setup.

We made high-precision inspections possible not just by relying on a smartphone, but by creating a measurement environment that takes into consideration characteristics of the vehicle used for measurement. The longitudinal profile is estimated based on vehicle response values, and the IRI/S032T (Class 2) is calculated by the QC simulation.

* Road Pavement Inspection and Testing Methods Handbook (June 2007: Japan Road Association). The research and development for the IRI estimation algorithm was conducted by a national university corporation, University of Tokyo.

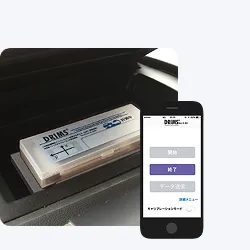

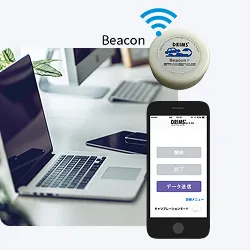

02The vehicle mounted device is removable. Communication cost is also reduced.

A dedicated case holds the iPhone secured in place with a magnet for an easy removal. The device can be managed at a business location when not in use, which reduces such risks as theft. Furthermore, the collected data is uploaded via mobile communications network from a Wi-Fi environment at a business location or the like.

* Mobile Wi-Fi routers are available on loan

03High-precision IRI estimation is possible regardless of where the device is mounted.

Conventional systems that use smartphones had constraints on where they could be mounted, but this system has adopted a half-car model that facilitates a free selection of mounting location at the front or rear of the vehicle. This makes mounting on various commercial vehicles possible.

04Operations are easy. Labor saving by using the "Beacon" is also possible.

The iOS app "iDRIMS measurement" (free) must be downloaded to operate the device. Basic operations are simple, requiring operations on the screen to "Start", "Stop" and "Transmit Data". Furthermore, using the Beacon automates button operations both in the vehicle as well as at the business location.

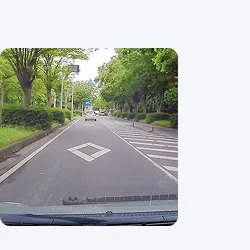

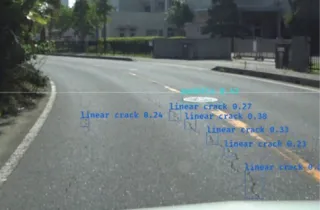

05Inspections with even higher precision are possible by linking images.

In addition to the data of DRIM, GPS-linked video images are captured. Roughness and anomalies can be confirmed visually. It is also possible to perform an automatic determination on damage types, by using AI with image analysis technology (deep learning).

-

Install the "DRIMS" on the vehicle used for measurement, then press the "Start" button.

* Automated in the Beacon area -

Road surfaces are automatically measured during ordinary duties (while in motion).

-

After returning to the business location, press the "Stop" button and take the "DRIMS" out of the vehicle.

* Automated in the Beacon area -

Press the "Send Data" button in a Wi-Fi area within your business premises.

* Automated in the Beacon area

Option

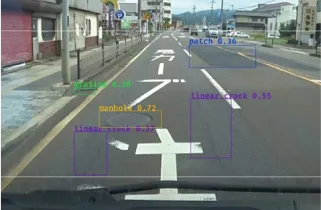

The road surface irregularity detection on road surfaces that are not rough is also available with the image analysis with AI.

Areas that require repairs, which are difficult to determine with the IRI alone, are analyzed with images.

The DRIMS is capable of performing highly precise inspections. Still, it is less likely to detect road surface irregularities such as cracks on road surfaces that are not rough, while detecting areas that require no repair work, such as areas with a series of manholes and joints. This is the reason why the video image of the road surface captured by the camera is used to perform image analysis with AI (deep learning). A rapid identification of areas that require repairs required by road managers is facilitated by supplementing the IRI, which is a quantitative indicator, with the image analysis.

Simply install a compact video camera available on the market

Easily set up by installing a video camera (Full HD type) available on the market, which is capable of acquiring GPS information on the dashboard or on the upper area of the windshield.

Various irregularities are analyzed based on camera video images.

A variety of abnormalities, such as linear cracks, alligator cracks, joints, potholes, manholes, and gratings, can be detected from video images.

Examples of irregularity detections

Manhole/Greating

Patching

Joint

Linear crack

Various Deformation

Alligator crack

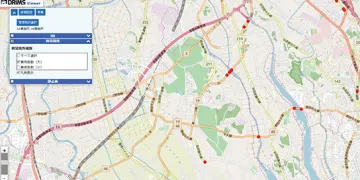

Road conditions are clearly visible on the web.

Facilitating map-based management is possible, which enables smoother repair planning.

-

Views of road surface conditions from various angles are available on the web.

-

Estimation of the IRI value

The IRI value of the targeted road line is displayed. The IRI values are color coded for five categories.

-

Display of areas with anomalies

Areas with irregularities within the driven lane are displayed. Irregularities are displayed in major and minor categories.

-

Display of road surface images

Captured images of the driven lane are displayed. Images can also be fast forwarded or rewound.

-

-

-

Facilitates rapid responses of reports from residents

Locations pointed out can be verified and their conditions determined instantly by using maps and still images. Rapid response is possible even to sudden changes of conditions, since short-term comparisons are possible depending on circumstances, rather than relying solely on annual and quarterly comparisons.

-

Operational costs are reduced by using open-source maps, which are available free of charge.

Operational costs are reduced by using open-source maps, which are available free of charge, for map data. We created an environment that can be used at a low cost. Map systems that are currently in use, as well as GIS and the like can also be integrated.

-